Gershin Electronics Ltd., established in 1994, has professional manufacturing experience in SMT, DIP, circuit board potting, packaging, and electronic product testing. The factory covers 28,500 sf, and which achieves high efficiency and quality products through the optimized assembly line layout. Our organization includes the Business Development Department, Material Department, Production Management Department, Finance Department, Quality Control Department, Manufacturing Department, and Technical Department. To develop and maintain an appropriate quality assurance system, the company utilizes several international standard certifications as the benchmark. In order to conform the requirements of ISO 14001:2015, the company has implements five production lines and it manufactures with Pb-free electronic production in the 24-hour nitrogen production mode.

Gershin's team shares a collective ambition to be the very best. The company's goal is to provide customers with the best quality products and services. For the purpose of ensuring the quality, cost, delivery, and service to achieve customers' requirements, the company has implemented the Enterprise Resource Planning system (ERP) since 2013. Later on, we adopted the Shop Floor Control System, EPS System, Intelligent Material Warehouse System, and precise testing equipment to strictly control the quality of the process. In 2019, the company was awarded the "Outstanding Business Performance Award" by the Ministry of Finance.

For various needs from customers, we cooperate and develop a number of peripheral products related to computer and network, wireless communications, medical equipment, and integrated circuits like automotive instrument control. Also, LED series products with energy-saving and carbon reduction; active RFID card is one of the many products designed and developed by Gershin.

We sincerely welcome EMS/OEM/ODM orders. We adhere to the policy and commitment as the customer first, value the intellectual property rights, and strictly maintain the confidentiality agreement. We look forward to hearing from you.

Gershin pursues a perfect quality assurance system and devotes itself to quality management for a long time. We have been awarded the quality standard certification since 2002 and have successfully renew to date. At present, Gershin follows ISO 9001:2015 as the baseline of quality control standard. In 2016, we acquired ISO 14001:2015 Quality Management System for Environment as a practical tool to manage our environmental responsibilities, and ISO/TS 16949:2009 Quality Management System for Automotive Related Products. We then renewed the latter to IATF 16949:2016 in 2019, and obtained the ISO 13485:2016 Quality Management System for Medical Devices. The ISO 13485:2016 demonstrates our ability to provide medical devices and related services that consistently meet both the customer and regulatory requirements.

Gershin provides outsourcing electronic parts, hardware, and PCB1 tailored to your requirements.

Gershin provides outsourcing electronic parts, hardware, and PCB <1> tailored to your requirements.

Gershin has more than 25 years of experience in the industry. We provide suggestions for product improvement and ensure the quality of the deliverables.

Gershin delivers electronic products, computer peripherals, and OEM or ODM services.

Gershin assists our client in product safety specifications, FCC, and patent application.

Gershin's professionals provide product design and evaluation, trial reports, improvement validations, product specification, data formulation, and design modification.

- Verify Project Information2

- Verify Project Information <2>

- Convert Engineering Data to ERP & EPS System

- Design and Model SMT Pallet/Carrier

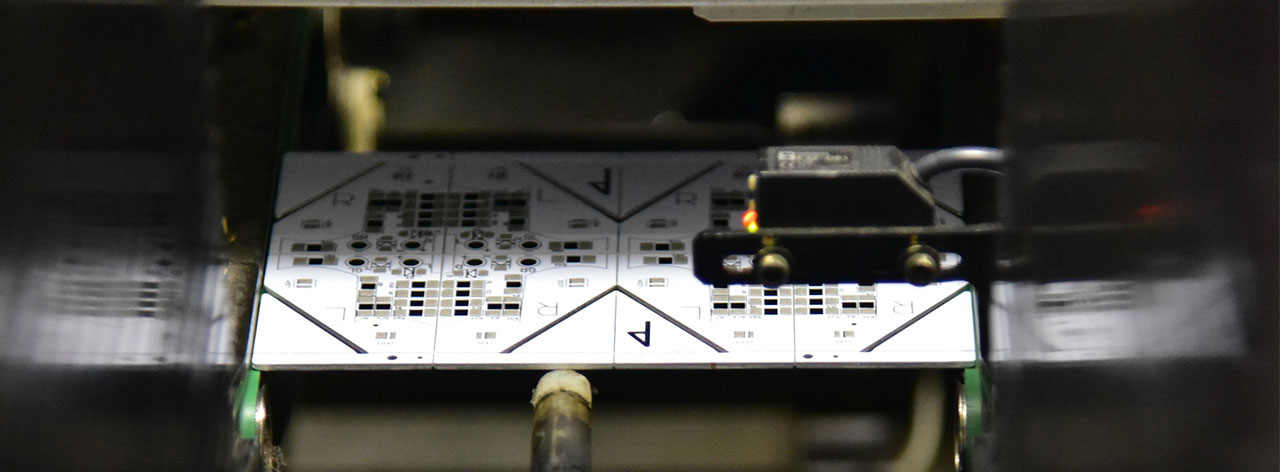

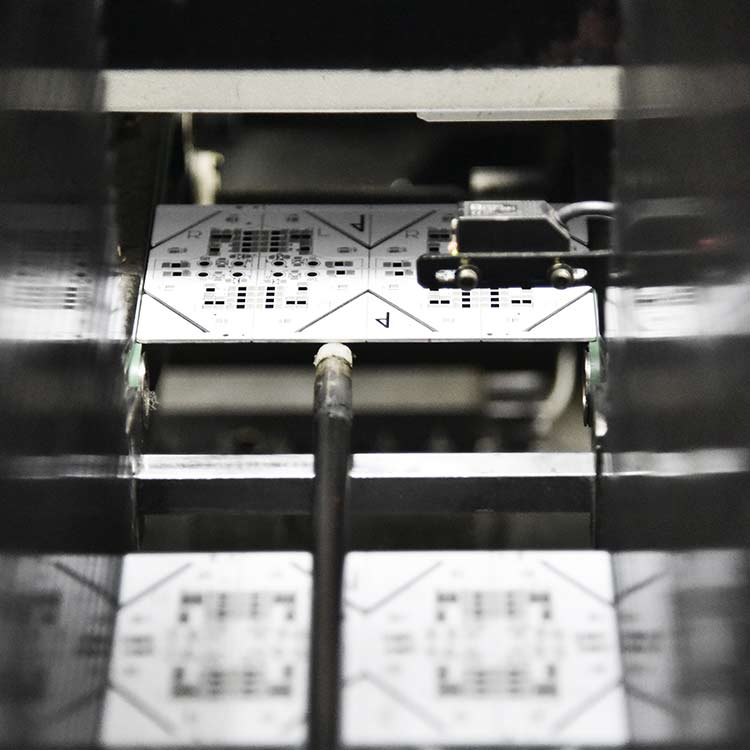

- SMT and Offline AOI Operation

- Testing Technology Adoption from Client

- Prototyping and Mass Production

- Identify Customer Needs

- Inquiry Based on BOM

- Purchase and Delivery under ISO standards

- Outsourcing/Consigning Parts Management

- Parts Inspection and Barcode Check

- Stock, Issuing, and Residual Parts Management3

- Stock, Issuing, and Residual Parts Management <3>

- Orders and Production Scheduling

- Delivery and Client Communication

- Information Sharing/Exchanging and Coordination

- SPI Programming

- Verify SMT Program and Precautions

- SMT Operation and First Article Inspection

- Temperature Control and AOI Programming

- Repair Defective SMD

- Preprocess DIP Parts

- Manual Thru-Hole and General Inspection

- Automatic Soldering

- Post-Soldering Inspection

- Manual Post-Soldering Adjustment

- Perform EMC Tests Based on the SOP

- Establish Testing Fixture and Maintenance

- Repair and Reinspect Defective Products

- Assemble Based on the SOP

- Product Packaging

- Outgoing Quality Control

Line5

Model6

Quantity

Capacity7

SMT Line 1

Yamaha Σ-G5S + M20

2

1,200,000 pc.

SMT Line 2

Yamaha M10 (*2) + M20

3

900,000 pc.

SMT Line 3

Yamaha Σ-G5S + M10 + M20

3

1,500,000 pc.

SMT Line 4

Yamaha Σ-G5S + M10 + M20

3

1,500,000 pc.

SMT Line 5

Yamaha i-PULSE M6ex (*2)

2

450,000 pc.

Line

Model

Quantity

Capacity8

DIP Line 1

Yuan Xing YX-LF310

1

40,000 pc.

DIP Line 2

Yuan Xing YX-LF310

1

40,000 pc.

DIP Line 3

Everprecision EP400-SR

1

2,400 pc.

Function

Model

Quantity

Solder Paste Inspection

VCTA V-850L

4

3D Automated Optical Inspection

Yamaha YSi-V

1

Automated Optical Inspection

Saki BF-Sirius

2

Automated Optical Inspection

Magic-Ray V8XL

1

BGA Rework Stations

Fonton 936-USB

1

X-Ray Inspection

Nagoya NXI-2000

1

Equipment/Line

Quantity

Testing and Packaging Line

1

Glue and Epoxy Potting Machine

1

Ultrasonic Welder

1

Line <5>

SMT Line 1

Model <6>

Yamaha Σ-G5S + M20

Quantity

2

Capacity <7>

1,200,000 pc.

Line

SMT Line 2

Model

Yamaha M10 (*2) + M20

Quantity

3

Capacity

900,000 pc.

Line

SMT Line 3

Model

Yamaha Σ-G5S + M10 + M20

Quantity

3

Capacity

1,500,000 pc.

Line

SMT Line 4

Model

Yamaha Σ-G5S + M10 + M20

Quantity

3

Capacity

1,500,000 pc.

Line

SMT Line 5

Model

Yamaha i-PULSE M6ex (*2)

Quantity

2

Capacity

450,000 pc.

Line

DIP Line 1

Model

Yuan Xing YX-LF310

Quantity

1

Capacity <8>

40,000 pc.

Line

DIP Line 2

Model

Yuan Xing YX-LF310

Quantity

1

Capacity

40,000 pc.

Line

DIP Line 3

Model

Everprecision EP400-SR

Quantity

1

Capacity

40,000 pc.

Function

Solder Paste Inspection

Model

VCTA V-850L

Quantity

4

Function

3D Automated Optical Inspection

Model

Yamaha YSi-V

Quantity

1

Function

Automated Optical Inspection

Model

Saki BF-Sirius

Quantity

2

Function

Automated Optical Inspection

Model

Magic-Ray V8XL

Quantity

1

Function

BGA Rework Stations

Model

Fonton 936-USB

Quantity

1

Function

X-Ray Inspection

Model

Nagoya NXI-2000

Quantity

1

Equipment/Line

Testing and Packaging Line

Quantity

1

Equipment/Line

Glue and Epoxy Potting Machine

Quantity

1

Equipment/Line

Ultrasonic Welder

Quantity

1

Gershin's QA/QC is consisting of the following standards: ISO 9001:2015: Quality Management System Standard, ISO 13485:2016: Quality Management System for Medical Devices, ISO 14001:2015: Quality Management System for Environment, and IATF 16949:2016: Quality Management System for Automotive. The entire plant and the manufacturing process are managed under MES and Shop Floor Control System.

All raw materials are monitored by the barcodes and checked before entering the production. Meanwhile, it is integrated within the EPS system and Intelligent Material Warehouse System to improve the efficiency and achieve our quality standards. As a whole, this MES tracks part usage, regulatory inspections, station control records, pass yield, and material sourcing.

If you have any questions or need more information about our company, get in touch with us through the following ways, or discuss with our Business Development team directly. We'd love to hear from you!

Address: 6F, No. 504, Yuanshan Road, Zhonghe District, New Taipei City 235, Taiwan

Telephone (Chinese): +886-2-2226-1096 #188

Telephone (English): +886-2-2226-1096 #588

Fax: +886-2-2226-1311

Email: sale@gershin.com.tw